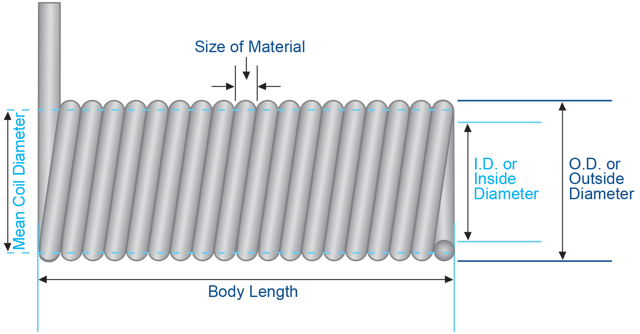

Torsion Spring Length

Torsion Spring Design Resources – Spring Design

Most torsion springs are close-wound, with body length equal to the wire diameter multiplied by the number of turns plus one. When a spring is deflected in the direction that will reduce the coil diameter, body length increases according to:

L = d(Nb + 1 + Ɵ )

Content Copyright Spring Manufacturers Institute, Inc.

This information is attributed to, and provided courtesy of, the Spring Manufacturers Institute, Inc. (SMI). Newcomb Spring and SMI provide this as advisory information only, and disclaim any and all liability of any kind for the use, application or adaption of material published on this web site.

Resource Illustration

Torsion Length Spring Diagram

For applications that require minimum hysteresis, spring should be designed with space between adjacent coils to reduce frictional losses.