Custom Software for Unmatched Precision

Our Own Metal Forming & Spring Coiling Manufacturer Software

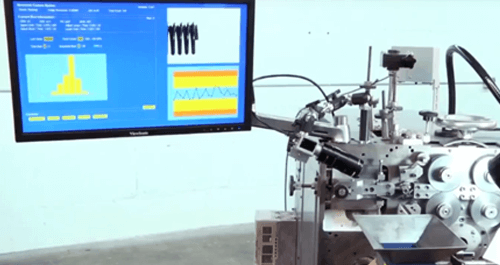

The integration of computerized technology and Newcomb Spring software allows for unmatched precision and compliance, with metal forming and spring coiling processes that can be customized to order requirements.

Custom Metal Forming Improved by Custom Software

As computerized technologies have become increasingly integrated with metal forming and spring coiling machinery, Newcomb Spring has led the industry in the development of our own software and systems. With a unique collaboration of skilled programmers and experienced metal forming and spring coiling personnel we have developed our own software solutions to improve quality control, efficiency and compliance reporting capabilities.

Precision Spring & Metal Form Quality

Our Innovation Team spearheads the development of our software and systems. Many of our CNC metal forming and spring coiling operations run on Newcomb Spring software, and deliver unmatched repeatability, speed and quality checks in real time.

With software that integrates laser measurement, camera measurement and other dimensional analysis systems into equipment operations, we are able to check parts as they are produced. Parts out of compliance can be immediately rejected and discarded. Our software also is able to adjust metal forming and spring coiling equipment without shut-down, reprogramming settings in response to part data. As set allowance perimeters are neared, an adjustment is triggered, and the system is recalibrated to maintain compliance to specifications.

Improved Metal Forming & Spring Coiling Efficiency

Traditional, basic metal forming and spring coiling operations required parts to be measured individually, often selected right off the assembly line. If parts were out of compliance, large batches of components had to be manually rechecked and often scrapped. For manufacturers with precision order requirements, these steps slowed production times, required extensive labor and increased waste – all which lead to inefficiency and increased costs.

Many of Newcomb Spring’s software solutions track spring coiling and metal forming operations right in the system software. Our modern equipment and state-of-the-art technologies provide an unmatched level of quality and repeatability, all with minimal labor.

Metal Form & Spring Manufacturing Compliance

With a combination of advanced machinery and Newcomb Spring software, our parts are able to meet extremely high levels of compliance, and can be custom manufactured quickly, accurately and to highly-unique order requirements. One of the most recognized examples of our software is the Newcomb Camera Gauge System, a dimensional analysis tool with reportable accuracy for spring coiling.