Variable Diameter Compression Springs

Compression Spring Design Resources – Spring Shapes

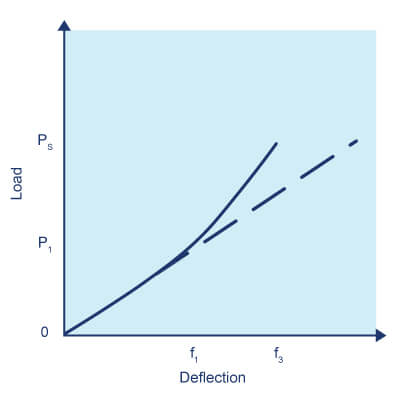

Conical compression springs, hourglass compression springs and barrel-shaped compression springs are used in applications requiring a low solid height, increased lateral stability or resistance to surging. Conical springs can be designed so that each coil nests wholly or partly into an adjacent coil. Solid height can be as low as one wire diameter. Rate for conical springs usually increases with deflection (see chart below) because the number of active coils decreases progressively as the spring approaches solid. By varying the pitch, conical springs can be designed to have a uniform rate.

To calculate the highest stress at a given load, the mean diameter of the largest active coil at load is used. Solid height of a uniformly tapered, but not telescoping, helical spring with squared and ground ends made from round wire can be estimated from:

LS = Na √(d2 – u2) + 2d

Where u = outside diameter large end minus outside diameter small end divided by 2Na.

Designing a variable diameter spring so that adjacent coils rub against one another during deflection increases resistance to resonance phenomena but may also shorten spring life due to wear.

Barrel and hourglass helical springs are calculated as two conical springs in series.

Content Copyright Spring Manufacturers Institute, Inc.

This information is attributed to, and provided courtesy of, the Spring Manufacturers Institute, Inc. (SMI). Newcomb Spring and SMI provide this as advisory information only, and disclaim any and all liability of any kind for the use, application or adaption of material published on this web site.