Custom Compression Springs

Newcomb Spring specializes in producing a diverse range of custom compression springs with a variety of shapes, sizes, and designs. Every compression spring is precision manufactured to meet even the most demanding specifications, resulting in quality, high-performance springs.

With more than a century of expertise in spring design and manufacturing, our team is ready to assist you with your order. We collaborate closely with you to enhance your design, helping to reduce compression spring manufacturing costs and ensure optimal fit and functionality for your parts.

Get a Compression Spring Quote Try our Spring CalculatorCompression Spring Capabilities

Material Shapes & Sizes

- .0015 to .625 inches (.038 to 15.875mm) in wire diameter

- Up to 2 inches (50mm) in bar stock

- Round wire

- Square wire

- Rectangular wire

- Special section wire

- Open-coiled

- Helical

- Hourglass

- Barrel

- Conical

Compression Spring Value Added Services

The following are only a portion of popular value added services we offer; this is not a comprehensive list. Please contact your local Newcomb Spring and discover what we can offer on your unique design.

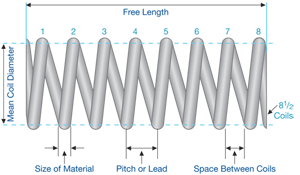

Compression Spring Design Information

What are Compression Springs?

Compression springs are open-coil springs that provide resistance when compressed. They are designed to absorb force and return to their original shape when the force is released, making them ideal for a wide range of applications. These precision compression springs are used to absorb shock in automotive suspensions, as pressure valves in medical equipment, and so much more! There are many design considerations that must be kept in mind throughout the design process for optimal spring performance.

Design Assistance

Tolerance requirements, squareness of ends, deflection, and slenderness ratio are often overlooked in the design process. Newcomb's sales and engineering staff will gladly review your compression spring specifications. From light duty compression springs to custom coil springs, Newcomb Spring can tackle your design challenges with unique solutions. We deliver high-quality compression springs customized to meet your exact needs.

Compression Spring Ends

Below are a few of the most common compression spring end types. Consult a Newcomb Spring design expert on the end type that will optimize your spring's performance.

Closed & Not Ground Ends

Closed end coil(s) with the wire not ground down. This is the most common end type.

Get a quote

Closed & Ground Ends

Closed end coil(s) that are ground down. This improves stability and vertical standing capability.

Get a quote

Open Ends

Open end coils can be ground or not ground, and rely on an external support like a rod or housing unit to maintain stability.

Get a quote

Reduced Ends

Reduced spring ends gradually decrease in diameter resulting in a conical shape. The decrease in diameter can happen throughout the entire spring or only a portion of it.

Get a quoteGrinding

Compression spring ends are often ground to allow the spring to sit squarely on the load-bearing surface. Grinding of compression springs also increases the number of active coils, which can result in higher loads or lower stresses. As a modern compression springs manufacturer, our facilities operate with a wide variety of equipment - from hand-operated grinding tools to automatic, high-speed vertical spindle disc grinders that can handle heavy-duty, large springs.

Watch our video on spring ends

Compression Spring Applications

- Aerospace

- Appliances

- Automotive

- Electronics

- Farm Machinery

- Furniture

- Medical Devices

- Sporting Goods

- Tools

- Toys

- Levers & Switches

- Fitness Equipment

- Industrial Machinery

- and more!

Product Gallery

Below are just a small selection of the compression spring shapes we have produced, including:

- Anti-Vibration Springs

- Auger Springs

- Automotive Springs

- Battery Contact Springs

- Coil Over Springs

- Gymnastic Springs

- Contant Coil Springs

- Die Springs

- Handle Springs

- Hose Guard Springs

- Firearm Springs

- Oil Filter Springs

- Latch Springs

- Magazine Springs

- Medical Injection Springs

- Suspension Springs

- Valve Springs

- Quick Release Springs