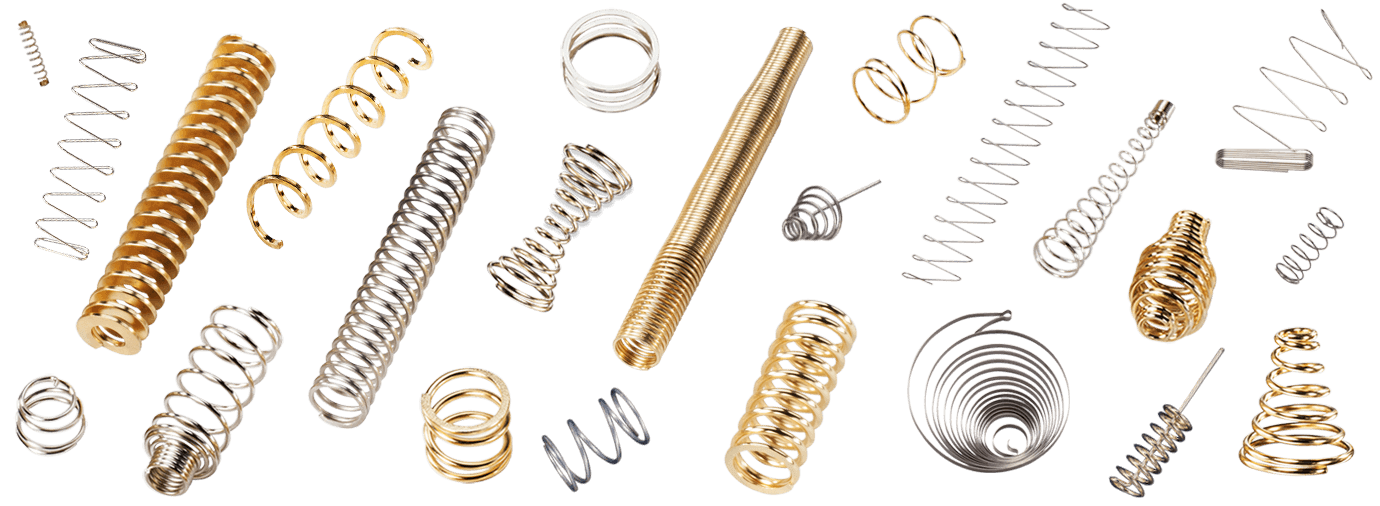

Magazine Springs

- .007 to .312 Inches In Wire Diameter for Round Wire

- Specialty Packaging Options Available

- A Quality Certified Magazine Spring Manufacturer

- All Orders are Manufactured to Customer Requirements

- Minimums May Apply

Magazine Spring Manufacturing Specifications

While we have listed some of the most common sizes, materials and manufacturing specifications, Newcomb Spring provides completely customized production on all magazine springs.

- Large Volume Orders, Short Runs & Prototypes – formed, assembled and packaged to meet your requirements.

- Proprietary Camera Gauge for Superior Quality – photographs and verifies each part, automatically adjusting production without shutdown.

- Kando Tech Centers – in all 8 manufacturing facilities you can work with our team and equipment to optimize designs and lower costs.

- Engineering Support – our team can provide expert design assistance on any order, or view our online spring design resources.

Magazine Springs Information

Newcomb Spring manufactures magazine springs, as well as magazine catch springs, for a variety of applications and for many mission critical functions. We produce magazine springs on high-speed equipment using the latest quality-control technologies. Our state-of-the-art operations allow us to rapidly produce custom magazine springs with strict compliance to specifications. We also offer advanced quality controls for orders with highly-exact requirements.

Magazine springs often function near the sold height, and understanding the requirements of how these springs function is critical in their production. Our experienced spring engineers can provide design assistance to advise on special considerations, functionality and to lower magazine spring manufacturing costs.

Magazine Spring Materials

Many customers request magazine springs manufactured using 17-7 stainless steel, though we are also able to utilize a wide variety of standard and specialty materials. Many of our magazine springs undergo secondary processes, such as heat-treating or stress relieving, to improve part lifespan and performance.

Custom Magazine Spring Finishing

As a custom spring manufacturer, Newcomb can produce magazine springs to meet your specific requirements. Due to the nature of many magazine spring and magazine catch spring applications, orders often utilize a selection of our advanced capabilities, including design assistance, advanced quality controls, assembly and finishing.

Special Packaging of Magazine Springs

Magazine springs are often utilized in unique and specialized applications, and it is extremely important that parts arrive ready for installation and that they are easy to use in your products. Our facilities offer an extensive variety of specialty packaging options for our springs, though many magazine spring orders request that parts are shipped:

- individually bagged

- in plastic / injected-molded trays

- packed to prevent corrosion

- using reinforced packaging for increased part protection

- labeled with information helpful for your shipping & receiving department using custom packages