Custom Micro Springs

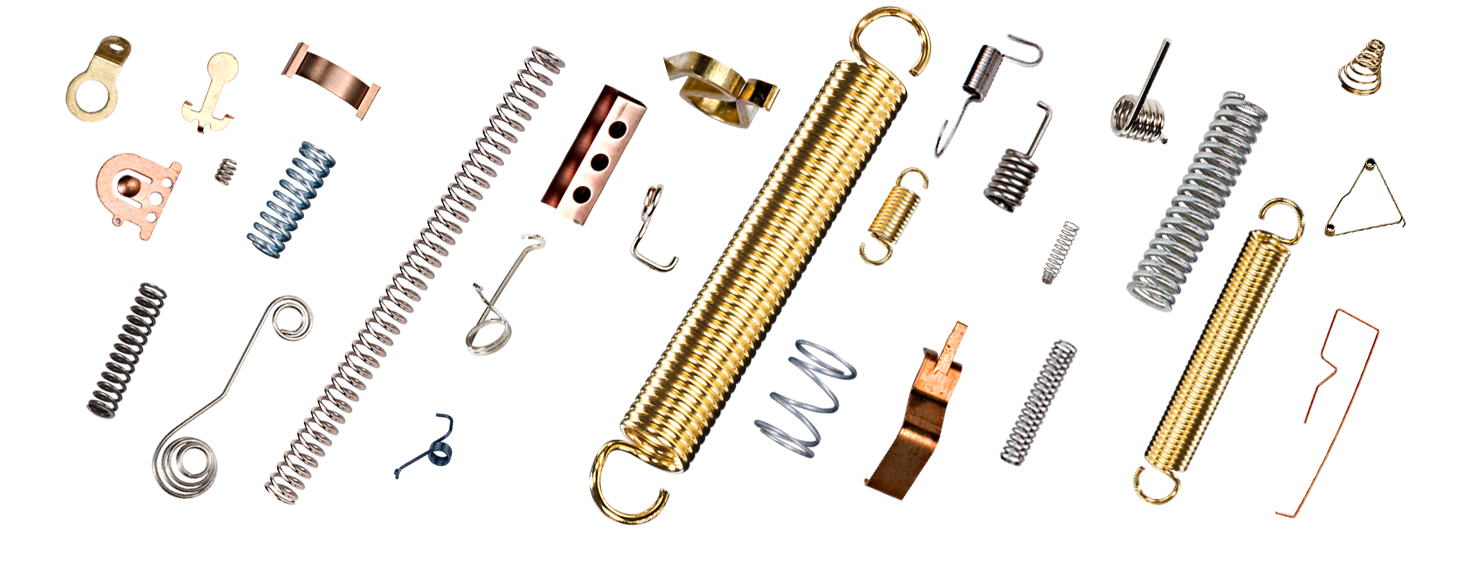

Newcomb Spring specializes in manufacturing high-precision micro springs engineered to meet the strictest specifications. Our custom micro compression, extension, torsion springs and components are designed for applications where tight tolerances and spacing requirements are critical.

With over 100 years of expertise in tiny spring manufacturing, our team works closely with you to optimize your micro spring design, ensuring superior performance while minimizing production costs.

Get a Micro Spring QuoteMicro Spring Capabilities

Material Shapes & Sizes

- .0015 to .006 inches (.038 to .152 mm) in wire diameter

- Round wire

- Square wire

- Rectangular wire

- Special section wire

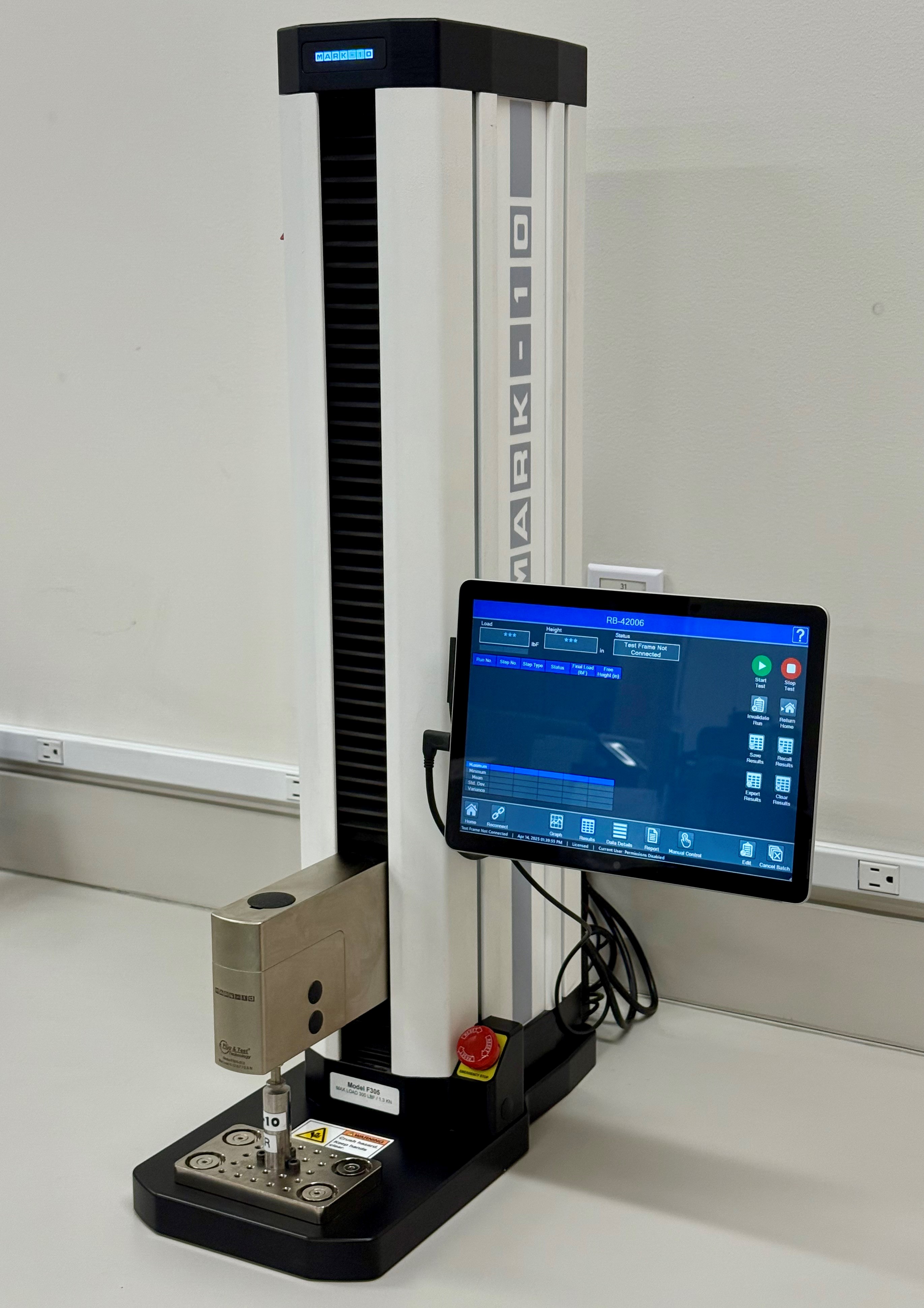

Micro Spring Value Added Services

The following are only a portion of popular value added services we offer; this is not a comprehensive list. Please contact your local Newcomb Spring and discover what we can offer on your unique design.

Micro Spring Design Information

What are Micro Springs?

Micro springs are miniature mechanical springs designed to provide precise force, tension, or compression in very small assemblies. Despite their tiny size, they function just like standard springs.

They are commonly used in medical devices, electronics, aerospace, automotive, and other industries where space is limited and performance is critical. Micro springs often require extremely tight tolerances and specialized materials to ensure reliability and consistency at a small scale.

Newcomb Spring manufactures small springs to precise specifications, offering custom solutions based on your application’s unique requirements.

Design Assistance

All of our small springs are available in varying lengths, in standard and custom spring body designs. As a manufacturer of completely custom micro spring components, Newcomb can produce parts to meet your needs and application. We offer design assistance on all micro spring parts we produce so that you receive a final product that’s optimized for max performance.

Micro Spring Applications

- Actuators

- Aerospace

- Auto-injectors

- Defense

- Fiber Optic Connectors

- Hearing Aids

- Laboratory Equipment

- Medical Devices

- Pacemakers

- Pens

- Precision Sensors

- Satellite Control Systems

- Surgical Staplers

- and more!

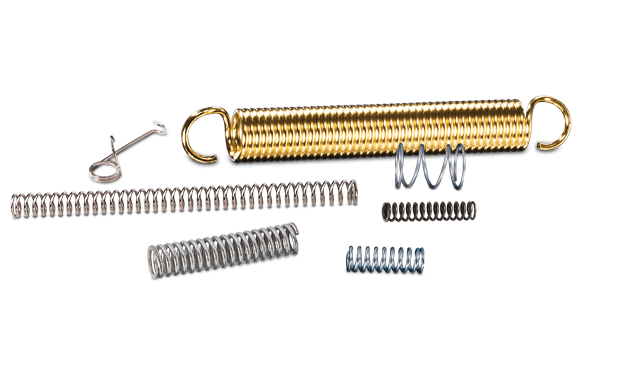

Product Gallery

Below are just a small selection of the micro spring types we have produced: