Spring Manufacturing Glossary of Terms

Backed by our long legacy of expert manufacturing

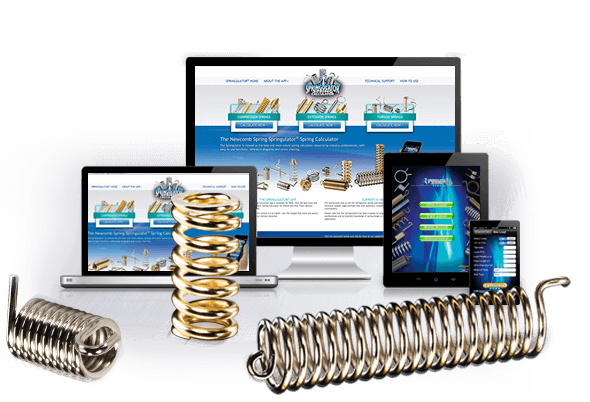

Newcomb Spring works to provide unmatched service in the precision manufacturing of custom springs, wire forms and metal stamped parts. For easy reference, we've included answers on our web site to some of the questions we are frequently asked. If you have a question you don't see here, please contact us and we will respond as quickly as possible.

Newcomb Spring has compiled a list of some of the phrases and terms associated with the spring and wire form industry. Please visit the following pages for in-depth information and resources sorted by product type:

Active Coils - Those coils which are free to deflect under load. More on Active Coils.

Bend Radii - a factor, based on the distance from the center of a spring to the outer edge of a spring and the material diameter, that can help to identify a spring’s limitations. More on Bend Radii.

Closed Ends - Ends of compression springs where pitch of the end coils is reduced so that the end coils touch. More on Closed Ends.

Closed & Ground Ends - As with closed ends, except that the end is ground to provide a flat plane. More on Closed & Ground Ends.

Deflection (F) - Motion of spring ends or arms under the application or removal of an external load (P). More on Deflection.

Free Angle - Angle between the arms of a torsion spring when the spring is not loaded. More on Free Angle.

Free Length (L) - The overall length of a spring in the unloaded position. More on Free Length.

Hooks - Open ends or hooks of extension springs. See hooks examples.

Hysterisis - The loss of mechanical energy from cyclic loading of a compression spring. More on Hysterisis

Initial Tension (Pi) - The force that tends to keep the coil of an extension spring closed and which must be overcome before the coils start to open. More on Initial Tension.

Load(s) - The force(s) applied to a spring and cause a spring to compress, extend, turn or change. Read about Compression Spring Loads. More on Load

Modulus of Elasticity - The elastic capabilities of a material. The higher the value (modulus) the stiffer the material. More on Modulus of Elasticity

Mean Coil Diameter (D) - Outside spring diameter (O.D.) minus one wire diameter (d). More on Mean Coil Diameter

Open Ends, Not Ground - Ends of a compression spring with a constant pitch for each coil. More on Open Ends, Not Ground.

Open Ends Ground - "Open ends, not ground" followed by an end grinding operation. More on Open Ends Ground.

Passivating - Acid treatment of stainless steel to remove contaminants and improve corrosion resistance.

Permanent Set - A material that is deflected so far that its elastic properties have been exceeded and it does not return to its original condition upon release of load is said to have taken a "permanent set". More on Permanent Set.

Pitch (p) - The distance from center to center of the wire in adjacent active coils (recommended practice is to specify number of active coils rather than pitch). More on Pitch.

Presetting - a secondary operation that increases a spring’s allowable elastic limits. More on Presetting.

Rate (R) - Change in load per unit deflection, generally given in pounds per inch (N/mm). More on Rate.

Remove Set - The process of closing to solid height a compression spring which has been coiled longer than the desired finished length, so as to increase the apparent elastic limit. More on Remove Set.

Residual Stress - Stress induced by set removal, shot peening, cold working, forming or other means. These stresses may or may not be beneficial, depending on the application.

Set - Permanent distortion which occurs when a spring is stressed beyond the elastic limit of the material. More on Spring Set.

Shot Peening - A cold-working process in which the material surface is peened to induce compressive stresses and thereby improve fatigue life.

Slenderness Ratio - Ratio of spring length (L) to mean diameter (D). More on Slenderness Ratio.

Solid Height (H) - Length of a compression spring when under sufficient load to bring all coils into contact with adjacent coils. More on Solid Height.

Spring Index - Ratio of mean coil diameter (D) to wire diameter (d). More on Spring Index.

Squareness of Ends - Angular deviation between the axis of a compression spring and a normal to the plane to the ends. More on Squareness of Ends.

Stress Range - The difference in operating stresses at minimum and maximum loads.

Stress Relieve - To subject spring to low-temperature heat treatment so as to relieve residual stresses.

Total Number of Coils (Nt) - Number of active coils (n) plus the coils forming the ends.

Wahl Factor - A factor to correct stress in helical springs effects of curvation and direct shear.