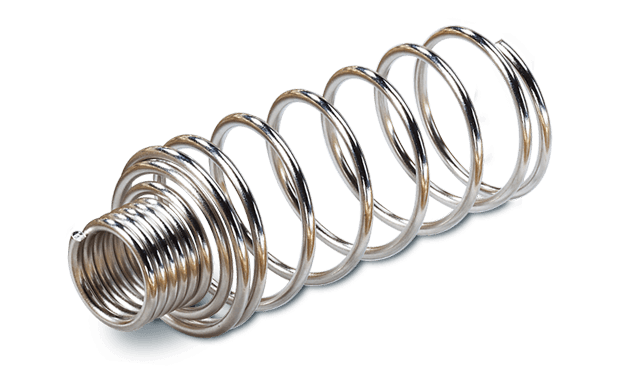

What Are Compression Springs?

Compression Spring Design Resources – Spring Overview

Compression springs are used to resist applied compression forces or to store energy in the push mode. Compression springs have the most common spring configuration and are found in many applications such as automotive, aerospace and consumer goods. While the most prevalent form of compression spring is a straight cylindrical spring made from round wire, many other forms are produced. Conical, barrel, hourglass, or cylindrical forms are available, with or without variable spacing between coils. Such configurations are used to reduce solid height, buckling and surging, or to produce nonlinear load characteristics. Energy storage capacity is greater for round wire compression springs than for rectangular wire compression springs and can be increased by nesting. Rectangular wire is sometimes employed to reduce solid height or increase the space efficiency of the design. Most die springs are made from rectangular wire for this reason.

Content Copyright Spring Manufacturers Institute, Inc.

This information is attributed to, and provided courtesy of, the Spring Manufacturers Institute, Inc. (SMI). Newcomb Spring and SMI provide this as advisory information only, and disclaim any and all liability of any kind for the use, application or adaption of material published on this web site.